Agreement extends stainless steel reach

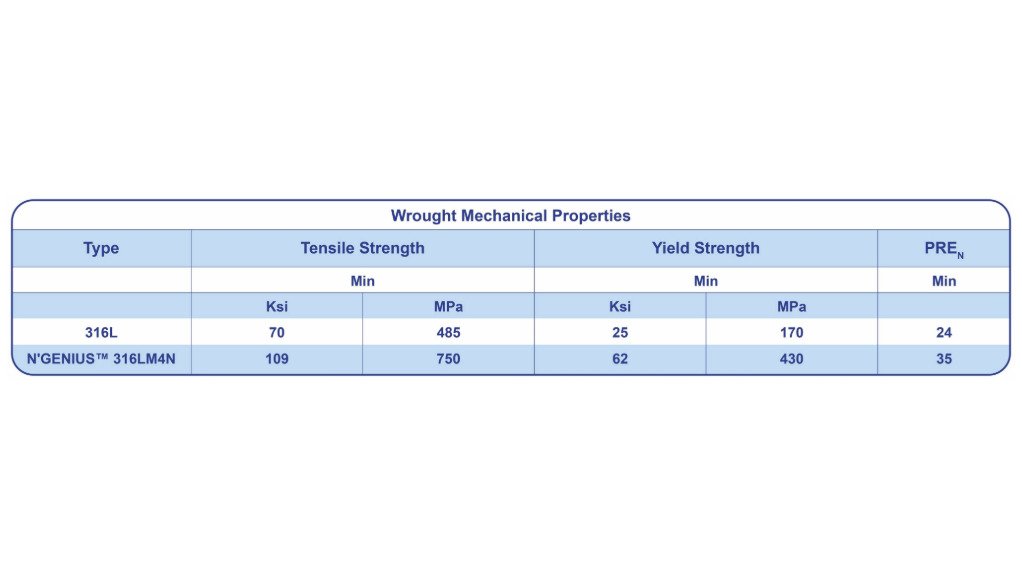

COVETED SPECS The N’GENIUS 316LM4N grade boasts significantly higher minimum yield and tensile strengths

Austenitic stainless steels specialist N’GENIUS Materials Technology has reached an agreement with UK-based stainless steel manufacturer Project Pipeline Supply (PPS) to sell and distribute pipeline and piping packages with products made from the N’GENIUS Series of high-strength austenitic stainless steels.

PPS provides pipes, fittings, flanges, components and specialist equipment for the offshore oil and gas, process, renewables and defence industries. The agreement will enable PPS to offer customers total packages of products made using the N’GENIUS Series.

The availability of N’GENIUS products through PPS is scheduled for the first quarter of 2025. However, this schedule could be accelerated because of ongoing discussions with potential customers across various sectors, including hydrogen, renewables, and oil and gas.

Along with being manufacturer and supplier, PPS will also provide technical advice – including materials selection and associated complementary products, in collaboration with N’GENIUS Materials Technology – for customers.

PPS will supply a variety of grades within the N’GENIUS Series, including N’GENIUS 316LM4N, which has received considerable interest for its potential applications in piping, says the company.

The N’GENIUS 316LM4N grade boasts significantly higher minimum yield and tensile strengths, compared to its conventional austenitic counterpart of 316L grade stainless steel.

As a result, products made using N’GENIUS 316LM4N stainless steel have significantly higher allowable design stresses than 316L, the company adds.

Many companies are looking for advanced materials for systems so that they can be used in ultradeep waters and under higher external loads, improve longevity and operate safely in more extreme environments, explains PPS MD David Toone.

Therefore, introducing N’GENIUS grades into the company’s range is relevant and, having seen the technical possibilities for N’GENIUS, PPS believes that the range will have a big impact on existing customers and create new opportunities in other industries.

“Together, PPS and N’GENIUS can provide expert advice to find the best solution for clients’ projects and this partnership provides the opportunity to source N’GENIUS product packages under one roof,” he adds.

N’GENIUS Benefits

The N’GENIUS Series, which is patented in more than 30 countries worldwide, offers superior performance, compared with conventional austenitic 300 Series stainless steels, while presenting a cost-effective alternative to higher-priced nickel alloys and high-alloy stainless steels, says N’GENIUS.

Conventional austenitic stainless steels possess relatively low strength and corrosion resistance, which significantly affects the designed wall thickness and weight of pipeline and piping systems that use these grades, N’GENIUS explains.

However, the “advanced mechanical properties” of the company’s grades allow for the fabrication of products with a reduced wall thickness, offering the potential to produce lighter and smaller structures.

Further, the enhanced corrosion resistance of the grades allows for equipment longevity, thereby reducing maintenance costs and enhancing operational efficiency by allowing for facilities to be designed for a longer service life.

Moreover, although higher-alloy stainless steels and nickel alloys are specified to provide better properties where necessary, the chemical compositions inherent in these materials often result in prohibitively high costs for specific projects.

N’GENIUS grades, on the other hand, provide a distinct economical advantage for manufacturers and end-users by containing the “optimum balance” of alloying elements, which results in the unique combination of mechanical and corrosion resistance properties.

Weathering Extreme Conditions

Experiencing high pressure levels, elevated or cryogenic temperatures, higher mechanical loads and aggressive process media present serious challenges for engineers specifying materials for pipeline and piping systems.

“None of the commonly used alloys can satisfy all these design requirements, often resulting in a compromise on selection and the risk associated with it,” says the company.

The limitations of many materials used on certain projects compels engineers to specify completely different alloys that are not always compatible with one another, N’GENIUS Materials Technology CEO Dr Ces Roscoe explains.

The N’GENIUS Series offers an extensive choice of corrosion-resistant alloy grades combined with ductility and toughness to function optimally at ambient, subzero and cryogenic temperatures.

The extensive grade range is suitable for a wide variety of service conditions and harsh environments, making it ideal for pipeline and piping systems in, for example, the energy, chemicals and petrochemicals sectors.

“With such a vast range of grades – all of them high-strength austenitic – the N’GENIUS Series enables engineers to use the same type of material, which meets the requirements of virtually every pipeline and piping package. It’s the total system material solution,” Roscoe says.

“This is the first of many exciting developments in the pipeline for N’GENIUS and we look forward to making further announcements in the near future,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation