When people talk about Energy “Management” often what they are only referring to is Energy Monitoring, which means gathering energy power data (i.e. kW, kWh, Power Factor), visualizing this data, archiving this data and then using this data to make calculated decisions. Also, some Energy Management systems only provide data on the Energy consumed, but this could be irrelevant unless also compared to production data, because as production increases the energy consumption would also increase. It would also be important to benchmark machines that perform a similar function against each other, for example if two compressors are running at the same load and one uses more energy than the other, then we can investigate why this is the case.

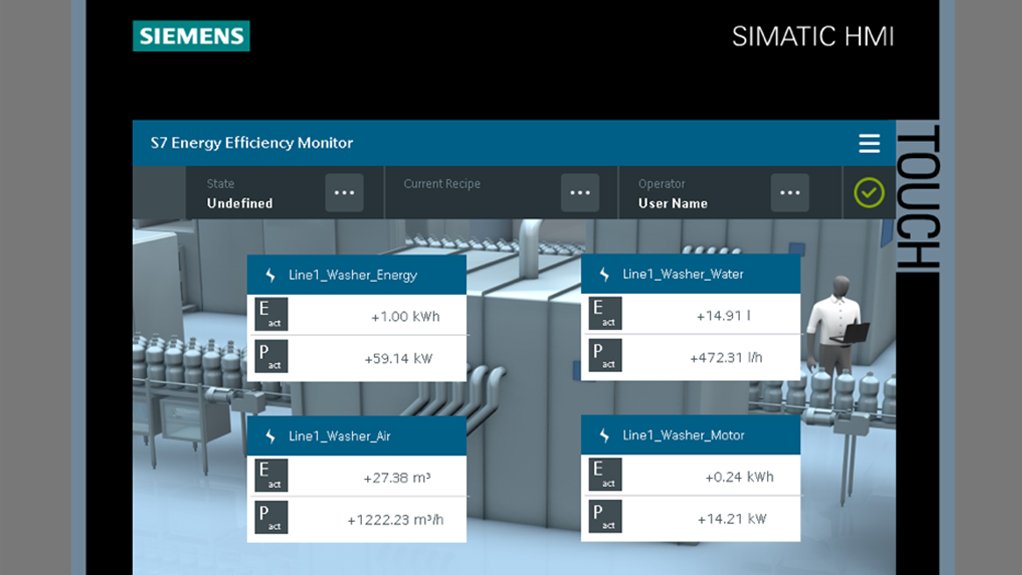

Using SIMATIC Energy Suite the engineering is made much simpler, as energy data is gathered very easily from Siemens energy monitoring devices (i.e. PAC3200/4200 Energy Meter, SIMOCODE, SINAMICS Drives, ET200SP AI Energy Meters etc), but also 3rd party devices can be incorporated like with the use of the “Modbus_TCP_energyAdv” library function block, which can read Modbus-TCP data out of an energy measuring device. The data is automatically then gathered into a structured data block within the S7-1500 PLC, this data can then easily be represented using a library of free pre-built faceplates on a Comfort panel, WinCC Runtime Advanced or WinCC Runtime Professional SCADA. Long term archives can automatically be created and stored on the S7-1500 CPU memory card or in WinCC Professional. Energy Suite is integrated all S7-1500 CPU’s with firmware version 2.0 or higher and as of TIA Portal V14 or higher.

The cost of electricity based on the current tariff applicable is another important factor that would need to be considered. These tariffs do change and therefore the changes would need to input into the Energy Management system to ensure budgets are not exceeded. These tariffs are provided by Eskom in South Africa, the structure of these tariffs is normally structured according to a High-Demand (i.e. June-Aug) and Low-Demand season (i.e. Sept-May). For each season there could also a Peak, Standard and Off-Peak tariff rate in cents/kWh. During the high season for consumers below 500V an example of the peak rate could be 320 c/kWh, while the standard could be 97 c/kWh and the off peak could be 53 c/kWh. Please however note that these are not actual values, but only estimates based on older information gathered. Energy utilities like Eskom typically offer reduced tariffs for constant, predictable demand profiles. Through contracts with limited peak loads, companies can optimize their consumption and reduce their energy costs. However, any violation of the specified peak load limits results in penalties and surcharges. With SIMATIC Energy Suite V16 Load Management, you can ensure that peak load limits are not exceeded – and do so in a fully automatic manner. Proactive load management with SIMATIC Energy Suite helps you to reduce energy costs by avoiding load peaks automatically and without affecting production.

If further detailed Energy data analysis is required at the management level then SIMATIC Energy Manager Basic or PRO would work well. There are also very nice wizards to easily integrate data from SIMATIC Energy Suite, WinCC SCADA and PCS7 into SIMATIC Energy Manager. Simatic Energy Manager Basic is ideal for a single plant, while the PRO version can be used to incorporate data from many plants.

SIMATIC Energy Manager brings many advantages:

-

It meets legal requirements for monitoring as per ISO 50001 (which could provide tax benefits) and reporting of greenhouse gas (CO2) emissions

-

Appropriate key performance indicators (KPI's) and data presentation options can be used to derive corresponding energy efficiency measures which, if successfully implemented, result in cost savings

-

The power monitoring feature supports a secure & reliable power distribution

-

Transparency at cost centre level increases employee awareness and forms the basis for a transparent and comprehensible design of targets or review of the achievement of goals.

-

Transparency paired with forecasting functionality increases planning security and opens up new opportunities in energy procurement

-

Energy controlling, with flexible reporting and analytics capabilities, help to ensure that efficient assets remain efficient

-

Openness is important and in addition to an interface to the SIMATIC Energy Suite, SIMATIC Energy Manager also offers the latest interface standards such as WinCC, PCS7, Desigo CC, OPC UA, OPC DA (DA, HA), OPC HDA, MODBUS TCP, ODBC, ASCII, XML, machine drivers to the S7-EE monitor and connectivity to our cloud based system MindSphere where a Energy Manager App is also available

-

Energy Manager Basic can be completely configured on the web and offers you an easy entry in the subject of energy data management. With the suitable license key you can always perform an upgrade from Energy Manager Basic to Energy Manager PRO.

-

Easy dashboard, chart and report configuration

-

Energy consumption and cost display at machine and cost centre level

-

Energy consumption or costs per piece, shift or the energy value add consumed energy

-

Batch analysis based on data from the short-term archive on the acquisition component/server

-

Benchmark of the same machine / same workpiece from different manufacturers

As mentioned above with power monitoring you can collect and analyse detailed data from your measuring devices to increase the availability of your power distribution and with just a view clicks, you can collect detailed data like current, voltage or CosPhi and can analyse it. In case of an outage in your plant you can use the detailed data to find the root cause like peaks or drops in voltage.

With the Power monitoring functionality, you can access data directly from MODBUS TCP devices and the data can be analysed using the Web client. For MODBUS devices templates can be defined and imported to reduce the engineering effort and to avoid configuration failures. With power monitoring up to 500 Devices can be connected. For each Device up to 25 data points can collected and represented online. For each acquisition component/server up to 1000 Power Monitoring data points can be archived using the short term (60days) archive on the acquisition component/server. The Desigo CC WebService interface can be used by Energy Manager V7.2 to collect historical data from the Building Management System.