Vesconite Bearings expanding into forklift part replacements

Polymer supplier Vesconite Bearings, which produces a proprietary brand of Vesconite bushings, wear plates and custom parts, has expanded its product portfolio to include replacement parts for forklifts.

Said to be one of the company’s most successful new applications, Vesconite engineering and sales manager Calvin Mpofu tells Engineering News the campaign is aimed at providing end-users with a more cost-effective solution, while simultaneously extending the life of a product.

Mpofu and his team have been hard at work for the last year, since the start of the campaign, with a targeted approach to solving the issue of replacing problematic forklift parts.

Considering that this is a new avenue of business for Vesconite, the forklift champion, as some like to call Mpofu, explains that the company’s replacement parts are made from a specialised hard-wearing thermopolymer designed for challenging operating conditions, which can have up to ten times the lifespan of bronze or nylon bushings, for example.

By combining internal lubrication, a low-friction coefficient and low wear rates, Vesconite polymers do not require external lubrication, even when conditions are wet and dirty.

This is why the company refers to its products as “better than original-equipment manufacturer (OEM) parts”, as these, in some cases, present challenges when the parts need to be greased, for example.

Mpofu explains that nylon was not designed specifically to be a bearing material and is a softer material which needs to be regularly greased to extend its lifespan, though he says this “wears the parts regardless of greasing”.

In the case of bronze, or any other metallic part, these parts also need to be maintained and greased often to reduce metal-on-metal friction, which not only leads to additional tasks that need to be completed, but also reduces the part’s lifespan as the metals were not necessarily meant to be used as a bearing material.

In the case of Vesconite, the “better than OEM” description comes into play as Vesconite’s specialised hard-wearing thermopolymers were designed for challenging operating conditions, and to be a bearing material, without the need for regular greasing or maintenance.

“We are able to reduce the grease that is used and provide a longer wear life, compared with OEM parts,” Mpofu comments, adding that “the longer parts last without needing to be repaired, the less money will need to be used to replace faulty parts”.

“The more interruptions you have because of faulty parts, the more you’ve got to do maintenance, which means you may end up losing money or business. By Vesconite providing parts that last longer, the interruption in between forklift use is reduced, or limited,” he elaborates.

The supply of forklift parts can take up to four weeks from part suppliers, which is an issue for forklift clientele who sometimes need parts at short notice, and Mpofu says Vesconite has simplified the design of its replacement parts in an effort to produce and supply the replacements parts faster.

The parts are manufactured in South Africa’s Free State, where the majority of the company’s machining and moulding capabilities are based.

“The simplified design helps us to make these parts faster, because they are easy to machine. If we can machine the component faster, we’re able to supply it much quicker and in larger quantities – which is our aim,” he notes.

Should a client, for example, need a replacement thrust bearing, Vesconite is able to machine this part within five minutes – “much faster than what it would take to produce an OEM part”.

This is of particular importance to forklift companies making use of older model or discontinued forklift ranges, as replacement parts may no longer be available or affordable to buy.

Older model or discontinued forklifts are often still included in a company’s fleet as these may allow for a specialised approach to certain applications, or be used for a shorter period, depending on the client’s requirements.

“Just because the forklift is discontinued, it doesn’t mean that the owner needs to dispose of it.”

Supplying replacement parts for these models, Mpofu explains, “helps to give forklift rental companies a variety of options on who to rent out to, and what to rent out”, all the while keeping savings top of mind.

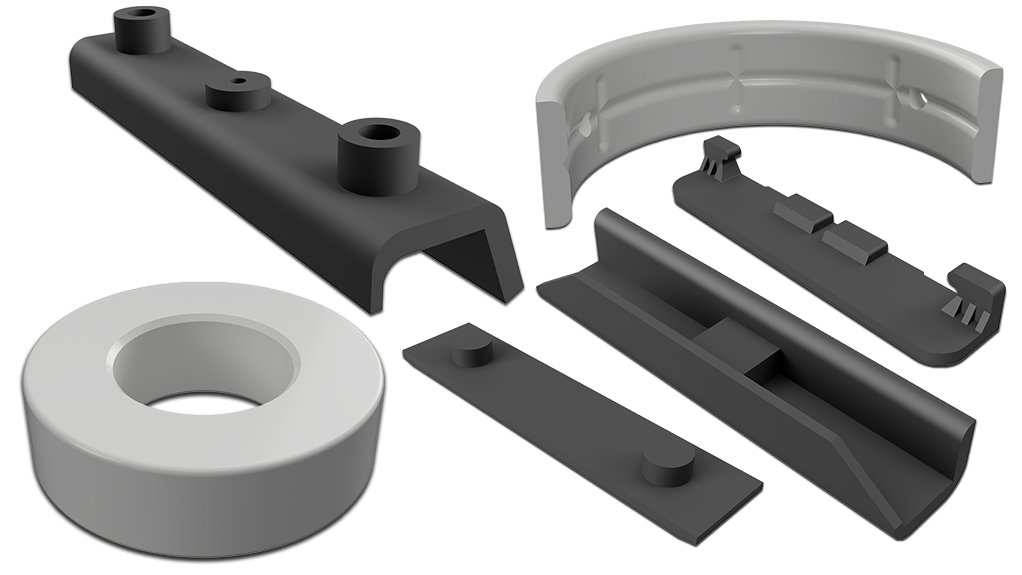

Vesconite can replace various forklift parts, with the most popular being side-shift wear pads, mast pivot and steer-axle bushings, king pin bushings, level and pedal bushings and gantry support bearings and cylinder bushings.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation