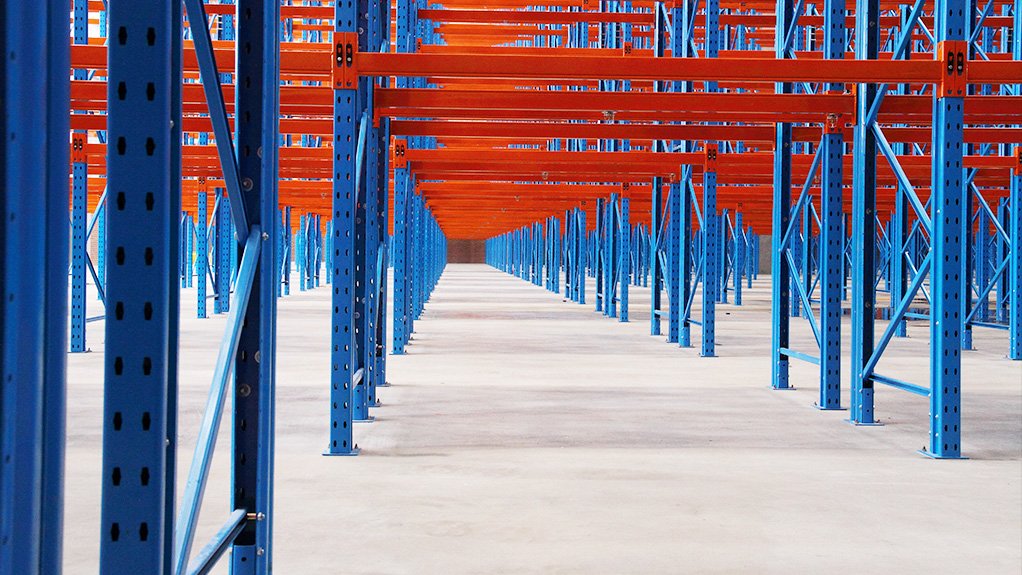

Heavy-duty upright beams handle heavier loads at higher storage levels

HEAVY DUTY Universal Storage Systems' new upright beams have been designed to accommodate loads of between 24 t and 30 t

Steel racking, shelving and mezzanine flooring manufacturer, supplier and installer Universal Storage Systems expects to launch its new upright beams, which will support heavier material loads, by the end of November, Universal Storage Systems sales director Jan Breytenbach says.

The company is in the final phases of testing and obtaining the engineering certification that confirms the load capabilities of the uprights, the design of which started in June 2014.

The product was developed in response to continuous innovation and technological enhancement that enable materials handling equipment to carry heavier loads and lift them higher in warehouses.

Breytenbach tells Engineering News that, while an original height cap of the materials handling equipment’s lifting capacity and storage heights allowed for these equipment and storage solutions to reach heights of up to 11 m, new equipment can now reach and handle material at heights of up to 17 m.

“With the new forklifts that can lift more weight higher, Universal Storage Systems’ new heavy-duty upright will accommodate the additional loads imposed on the racking systems,” says Breytenbach.

He explains that the new upright will have an increased base of 103 mm, compared with the current 82 mm, while the wall thickness of the upright material will increase to 3.0 mm and, potentially, 3.5 mm.

The upright, applied in warehouse racking applications for pallet storage and pick mezzanine, has further been designed to accommodate loads of between 24 t and 30 t, Breytenbach notes, adding that the load will depend on the thickness of the material.

Although the company currently manufactures uprights that can carry loads of up to 30 t, Breytenbach notes that these uprights are used in composites, where two uprights are butted back to back to accommodate the loads.

Additional factors prompting the need for these uprights include the increasing costs of acquiring and owning land, as well as the costs involved in warehouse and associated infrastructure construction, he notes.

The sizes of traditionally large warehouses are being waived in favour of smaller warehouses and smaller aisles, where more vertical space is used. This requires racking systems to handle higher and, therefore, heavier load stacks.

Project Focus

Universal Storage Systems is installing a multimillion-rand distribution centre warehouse in Nairobi, Kenya, for a South Africa-based pharmaceuticals company.

Installation started this month, with project completion expected by the end of October.

Universal Storage Systems will install racking to store pallets in bulk and small parts. The racking and associated equipment used in the project are designed and installed according to the Storage Equipment Manufacturing Association’s (Sema’s) standards for storage.

The Sema trade association promotes “the safe design, installation and use of storage equipment manufactured and supplied by storage equipment companies”. Breytenbach emphasises that Universal Storage Systems employ Sema-accredited inspectors to ensure installations are completed according to Sema’s required standards.

Meanwhile, another project under way is a pushback, pallet- racking storage system for a Gauteng-based printing company. “The pushback system entails putting a pallet of product onto a trolley, which pushes the first pallets to the back of the system for storage, while the second pallet is then stored and followed by a third, a fourth and so on,” Breytenbach explains, adding that the storage system uses the ‘first in, last out’ principle.

The five-pallet-deep, three-pallet-high trolley pushback can accommodate more than 2 400 pallets at any stage. System implementation started in the middle of July and was completed this month.

Continental Scope

Another key focus area for Universal Storage Systems this year includes the expansion of its market footprint on the African continent.

He emphasises that there are significant opportunities in Africa and, although the company currently has several distribution agents, including those in Namibia, Botswana and Zimbabwe, it will focus on creating a distribution network in, for example, Kenya, Angola and Ghana.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation