Schools driving demand for Enviro Loo industrial model

SOUTH AFRICAN SOLUTION The Enviro Loo industrial model can accommodate up to 40 users a day, and about 110 000 units have been supplied to date

Developed in 1996, the industrial model from dry sanitation systems supplier Enviro Options was added to the Gauteng company’s offering in response to the need for a high-usage dry sanitation model.

The Enviro Loo industrial model can accommodate up to 40 users a day, and about 110 000 units have been supplied to date. The units are supplied worldwide, with Enviro Loo involved in ongoing provincial rural schools and housing programmes mainly in Limpopo, Mpumalanga, the North West and the Eastern Cape.

“There is increasing demand for our products in light of the growing call for dignified and safe sanitation in South African schools.The ongoing problem of water scarcity is also highlighting the need for sustainable sanitation products that do not rely on water to operate,” says Enviro Loo marketing consultant Sarah La Trobe.

The company started manufacturing dry sanitation units in 1993 to help provide a dignified dry sanitation alternative to the pit toilets that were the only available option at the time.

“Our biggest market for the industrial model, or the I1040, are schools and health clinics, particularly in rural areas, that have no access to piped water or waterborne sewage systems. These require a high-usage application,” notes La Trobe.

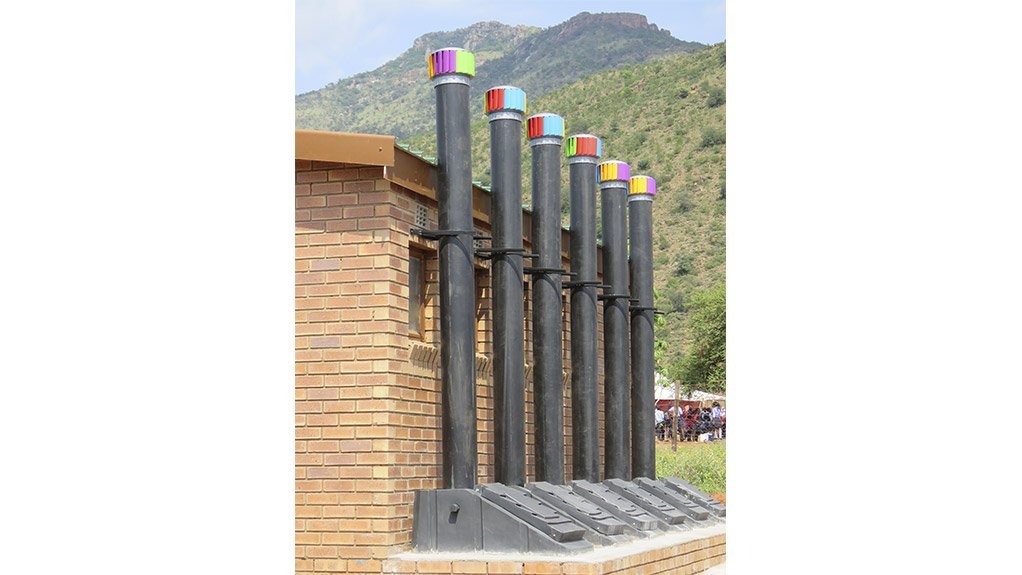

As with all Enviro Loo models, the industrial model comprises a fully containerised unit with an inlet pipe and vent extraction unit at the top. It has a ceramic toilet bowl similar to those used by waterborne toilet systems that is available in a standard or junior size.

Liquid waste drains to the bottom of a container, while solid waste remains on the drying plate. The waste is exposed to a continuous flow of air and an organic starter pack. Air is extracted through the extraction unit at the top with air being drawn into the container through the inlet vent pipes and toilet bowl.

As the air moves through the system, it dehydrates the solid waste on the drying plate. The liquid that has drained to the bottom of the container evaporates. Sunlight increases the ambient temperature within the container and intense heat, prolonged retention periods and oxygen-rich air dehydrate and decompose the waste.

“The human waste is converted into an inoffensive dry stabilised material that is roughly 5% of its original volume,” explains La Trobe.

Negative pressure in the container prevents odour from escaping through the toilet bowl or air inlet pipes and it is vented out by the wind-driven extractor.

“The client is normally responsible for building the top structure or ablution blocks around the installed unit,” explains La Trobe.

Installation, which is overseen by Enviro Loo, is relatively simple, as it does not require connection to any water or power systems. A hole is excavated and the appointed contractor constructs the below-ground vault according to Enviro Loo’s supplied specifications.

Once the Enviro Loo components are installed into and on top of the vault, a concrete slab is cast. The ablution block is then built around the unit and/or units. “Our team issues a compliance certificate once the installation has been checked and verified. Each new Enviro Loo unit comes with a two-year service plan as well as operation manuals and posters,” adds La Trobe.

Enviro Options has 48 full-time employees and is contracted to nine small, medium-sized and microenterprises (SMMEs) which, in turn, directly employ another 27 people for Enviro Loo-related works.

“We aim to create employment where possible by training and employing local SMMEs or community members to carry out installation, servicing and maintenance of our products,” points out La Trobe.

All the components and materials used in the manufacture of the units at Enviro Loo’s Chamdor factory, in Krugersdorp, are sourced locally.

“Enviro Loo was the recipient of the 2017 Frost & Sullivan Best Practices Award for the Southern African Dry Sanitation Company of the Year and the Enviro Loo was awarded the 2019 Eco-Logic Gold Award for its water-saving properties,” concludes La Trobe.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation