Logistics, NEVs in focus for next phase of automotive industry growth

Efficient logistics to move vehicles and automotive components up and down the value chain and adapting the local industry to new energy vehicles (NEVs) is crucial to shape the trajectory of the industry into the future, industry development agency Automotive Industry Development Centre (AIDC) chairperson Meloney van Eck said this week.

Speaking at a Gauteng government- and AIDC-hosted automotive industry roundtable discussion, in Midrand, on May 9, she said it was important for industry leaders and experts to discuss logistics in the automotive sector and to explore the growing NEV landscape to shape the way forward for the industry.

"Logistics is the backbone of the industry, and involves orchestrating the movement of vehicles, components and services. It is critical for the industry as it navigates the era marked by increasing global demand and complex supply chain dynamics.

"Logistics has been marred by some problems and is not running smoothly. It is important for use to get industry experts to give us a sense of what solutions we can implement so that we can determine what we must achieve in the next five years," she said.

The industry needs to embrace innovative logistics solutions and unravel the problems, not only to optimise operations, but to fortify the resilience and sustainability of the industry in the face of evolving market dynamics, said Van Eck.

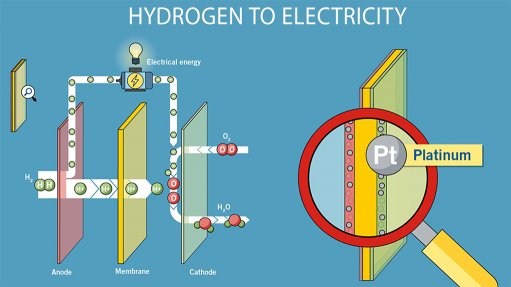

Further, the shift to NEVs, including electric vehicles and hydrogen-fuelled vehicles, represents a transformational trend in the automotive industry, owing to growing environmental concerns and regulations leading to momentum to clean up and make transportation solutions more sustainable.

"The discussions today and in the industry more broadly must focus on the opportunities and challenges with the integration of NEVs into the automotive ecosystem, including infrastructure development, market dynamics and the required policy framework," she said.

The AIDC has also made an additional 100 ha of land, adjacent to its 60 ha facility in Rosslyn, available to contribute to growth of the industry. Additionally, development plans for an inland port to serve the automotive industry were in the pipeline, she added.

The AIDC's automotive supplier park, in Rosslyn, hosts major multinational companies, with some companies distributing their aftermarket parts from this facility into Southern Africa, said AIDC CEO Andile Africa.

"We need to address the challenges with logistics. However, while some black entrepreneurs have become part of the supply chain of the automotive industry, discussions with original-equipment manufacturers (OEMs) and tier-one and -two suppliers to award purchase orders to these new entrants have been difficult.

"The AIDC has a robust incubation programme for young, black entrepreneurs to become part of the automotive supply chain. Some purchase orders awarded to these companies have enabled them to graduate to suppliers, and some have done very well.

"However, government has spent significant amounts of money on infrastructure for the automotive industry and the development of local suppliers, but the industry is not replicating the momentum in pushing the transformation agenda," he emphasised.

Meanwhile, in a separate panel discussion, Industrial Development Corporation (IDC) special economic zones and clusters development finance specialist Stieneke Jensma noted that Trade, Industry and Competition Minister Ebrahim Patel had reported that about 1 700 black industrialists had been developed by the department's black industrialist programme, employing about 160 000 people and generating revenues of about R183-billion a year.

"Development of black industrialists is happening, and companies are benefitting and people are being hired to work in these companies," she emphasised.

In another panel discussion, industry association the National Association of Automotive Component and Allied Manufacturers executive director Renai Moothilal emphasised that the country had strong capabilities for producing components, centred in Gauteng, and that South Africa had been making vehicles for more than 100 years.

"The automotive industry has been responding to changes in technology for as long as it has been producing vehicles. The component manufacturing base is ready to respond to the changes in the industry. When NEVs are assembled in South Africa, the component suppliers will be ready," he noted.

Further, components suppliers also have the capability to significantly increase the number and value of components.

"The value of components imported into South Africa in 2023 increased by almost 40% compared to the prior year, but the country has not achieved its 40% localisation goals.

"The automotive industry masterplan's target was 60% localisation by 2035, and we had around 38% localisation in 2017. We only achieved a 39% localisation rate during the first quarter of this year.

"This is not good enough and we have to push harder by increasing the rate of domestic procurement and unlock the opportunities we want to see in the country," he said.

OEMs have been doing good work introducing new entrants to the market, and the Automotive Industry Transformation Fund is a unique structure to support black industrialists.

"However, unless we massify localisation and get more procurement, then we are fighting about crumbs and trying to divide a small cake. Increasing localisation, especially on the back of our strength in component manufacturing, is what we need to do," said Moothilal.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation