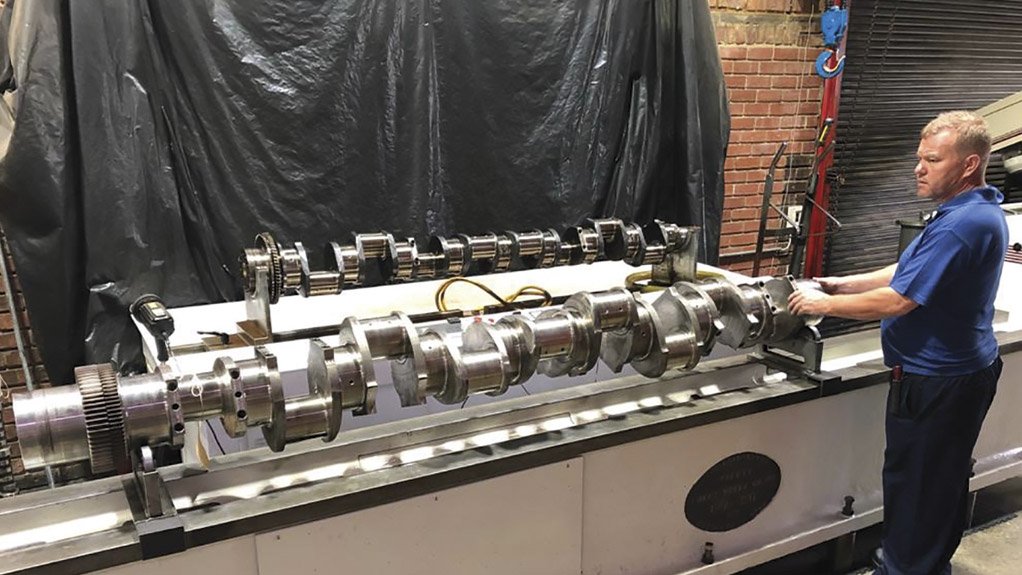

Crankshaft for Cummins QSK 78 diesel engine gets a turn

A crankshaft belonging to an 18 cylinder Cummins QSK 78 diesel engine being remanufactured at Metric Automotive Engineering.

Metric Automotive Engineering operates the latest state-of-the-art crankshaft polishing machines.

Remanufacturing a crankshaft at Metric Automotive Engineering.

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Currently Metric Automotive Engineering is remanufacturing a crankshaft belonging to an 18 cylinder Cummins QSK 78 diesel engine. The 4000 hp engine powers a rigid frame dump truck in an open cast mining operation, and as can be expected works under arduous operating conditions.

Currently Metric Automotive Engineering is remanufacturing a crankshaft belonging to an 18 cylinder Cummins QSK 78 diesel engine. This 4000 hp diesel engine component, 2.7 metres in length, is easily accommodated on the company’s crankshaft polishing machine.

The large engine powers a rigid frame dump truck in an open cast mining operation, and as can be expected works under arduous operating conditions.

Andrew Yorke, operations director at Metric Automotive Engineering, explains that the engine had reached its scheduled overhaul hours and the engine components had come into the facility for assessment and remanufacturing to OEM standards, where necessary.

The diesel engine component’s including the crankshaft, camshaft, conrod, block and heads arrived at Metric Automotive Engineering’s well-equipped facility where they were cleaned using specialised high pressure steam and ultrasonic cleaning processes.

“Cleaning is vital to facilitate visual inspection and following this, components are sent to the dedicated component sections at our facility where a skilled automotive machinist conducts a full assessment on the integrity of the component using OEM specifications and guidelines,” Yorke says.

In this particular instance, the crankshaft integrity was favourable and the component only requires surface polishing of the journals. Yorke says this a great example of an effective lubrication filtration system and scheduled preventative maintenance helping to reduce long term operating costs by preventing wear and damage to the crankshaft. This results in a less costly remanufacturing process being required to return the crankshaft to OEM specification.

Metric Automotive Engineering has a comprehensively equipped remanufacturing facility which can handle large diesel and gas engine components with ease. Competent technical personnel receive ongoing training and development to ensure they are kept abreast of the latest technology. ISO driven quality standards and a high level of accountability ensures that customer receive remanufactured components that meet and often exceed OEM specification.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation